| Fault Gas Triangle

for Transformer Diagnostics 1. Situation for Diagnostics |

||||||

|

IEC 60599 describes transformer diagnostics on the basis of gases which are dissolved in oil and free. The study of several years of statistics of gas chromatographic laboratory analyses (DGA) with 5 (H2, CH4, C2H2, C2H4, C2H6) or 7 (additionally C3H6, C3H8) fault gases has led to value ranges for three quotients dependent on types of fault. The practical application with the help DGA interpretation tables for the determination of the six types of faults is supported by diagrams showing these quotients. What is visually more interesting is the Duval triangle which is also listed and uses a diagram of the fault gases CH4, C2H2 and C2H4 that is transformed to 100%, thus using the different energy densities of formation for diagnostics. The triangle can be used directly in its visual form and shows that diagnostics is also possible with three fault gases only. In practice, this can lead to diagnostic problems, e.g. in case of partial discharge and of leakages in OLTC vessels. The reason is that hydrogen is not included. |

||||||

2. Online Diagnostics with the Fault Gas Triangle |

||||||

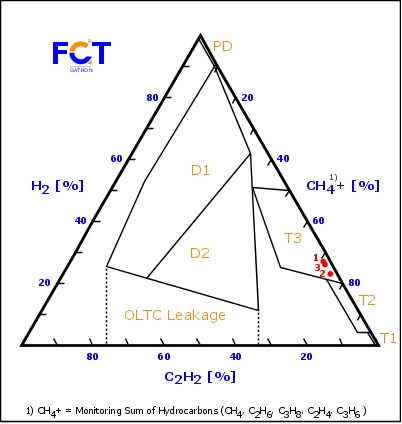

A new, powerful tool for diagnostics

has been developed. It is based on the assignment of the gases to the main fault types:

Fig. 1 Fault Gas Triangle for the diagnostics after IEC 60599 • diagnostic point of the operating example The result is a closed diagram which includes all fault gases. For the practical application of the gas triangle, it makes no difference whether the monitoring sum is measured with a sensor or calculated with the help of laboratory analyses. The concentrations of CH4+, H2 and C2H2 are transformed to 100% and then the registration in the fault gas triangle made. The conditions of use are the ones laid down in the standard: typical concentration values of the fault gases, additionally online CH4+ > 200 ppm and the gas production rates known. For free gases of the Buchholz relay, it is necessary to use a modified procedure: first they are tested in terms of the equilibrium criterion, then they are corrected to the original composition on the fault location and finally the CH4+ content is calculated from them. For diagnoses it is necessary to visualise the fault types. This can be done using the .diagnostic schemes (IEC 60599, MSS, Rogers, etc.) known. The marked areas in the fault gas triangle in Fig. 1 were calculated for the six fault types from the value ranges of IEC 60599.  TGM-D) "/> TGM-D) "/>Fig. 2 Operating diagram for the online diagnostics (TGM-D1)) |

||||||

3. Practical use |

||||||

| The typical application of the fault gas triangle can be demonstrated by a practical example.

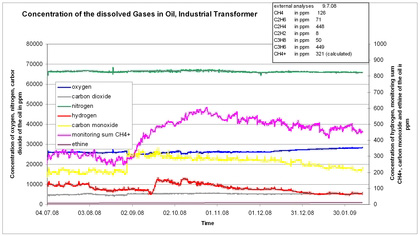

The operating diagram of a suspect industrial transformer is shown in Fig. 2. The TGM-D1) contains a sensor block which can measure the CH4+ content directly. Additionally, an external laboratory analysis of the first fault period (EGS1)), 09.07.2008) is shown in the diagram. On 02.09.2008, the second fault period begins, first seen in the operating diagram through the presence of CH4+ and then later of H2 . The measured results are displayed in the fault gas triangle: TGM-D1) of 09.07.2008 1•, EGS1) of 09.07.2008 2•, TGM-D1) of 20.09.2008 3•). Fig. 1 shows that all three diagnostic points are in area T3. The EGS1) analysis of 09.07.2008 on basis of IEC 60599 with the evaluating procedure known leads to the same result T3. The fault gas triangle offers the following advantages for diagnostic purposes:

The application of the fault gas triangle will lead to statistics of the fault types which are independent of the diagnostic schemes known. This will open up new possibilities for better diagnostic performance. 1) Transformer Gas Monitor TGM-D and Extraction Gas Sampler EGS are GATRON products, which are quality controlled (N2IS based ! ®). |

||||||