| Quality Assured Transformer Diagnostics (GTD) Concept |

||||

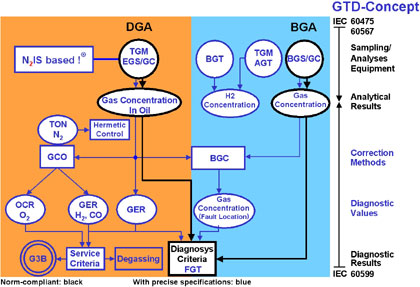

Norm-compliant transformer diagnostics uses laboratory results obtained from dissolved gas analysis (DGA) as well as from Buchholz gas analysis (BGA). The correctness of the results can be affected by non-existing hermetical conditions (sampling, transport, storage). The diagnostic capabilities could be increased by making the standards more precise. This aim is pursued by the GTD concept, which includes the quality assurance of the DGA results as well as the application of correction methods for the determination of diagnostic values from the analytical results. The GTD concept can be implemented in the form of the products of GATRON GmbH.

The correction method for the gas concentration in vessel oil is applied to the small oil soluble gases (H2, CO, O2) in open type transformers. The correction method for the Buchholz gas analysis uses all fault gases and is also useable for closed transformers. The openness of transformers can be characterised with the transformer openness number (TON). The TON is determined with the help of N2 resaturation measurements and should be recorded in the life file of the transformer. With the help of the correction method, in which the TON is integrated, the oxygen consumption rate (OCR) as well as the gas emission rate (GER) for H2 and CO can be determined. The current formation of rates from the concentrations guarantees the reliability of diagnosis. For closed transformers, hermetic control is possible. Gas concentrations on the fault location can be determined from Buchholz gas analyses using the correction method if the Buchholz gas is directly separated from the oil at the moment of signalisation and there is a DGA at the same time. As a diagnostic result, the fault type and intensity can be determined more reliably than before. Additionally, it is possible to check if the service criteria are reached. In special fault stages, a time limited stabilisation of the transformer operation through degassing and monitoring can be performed. For substance conservation by post installation hermetic sealing, breathing buffer boxes G3B can be installed and monitored. |

||||

| ||||